Dermoid Copenhagen Design Week

A research collaboration between CITA and SIAL, RMIT.

Danish Museum of Art & Design.

The link of generative design tools and simulation allows the exploration of new architectural spaces that are in balance with material and structural capacity. The Dermoid demonstrator is the two years research into the integration of material performance into architectural design that was conducted in the frame of the VELUX guest professorship of Prof. Mark Burry (SIAL) at the Centre for IT and Architecture (CITA) in Copenhagen / Denmark.

Using timber as a case the research focused on the introduction of the materials pliability into structures and development of computational design environments that allow an intuitive material led design practice. While there is significant awareness of the potential of design taking material behaviour into account there is currently little applied research into how to engage with this in digital design space. The key research inquiry undertaken in Dermoid is a speculation on the kinds of new design practices and interfaces needed to be able to create solid and useful knowledge transfer between the fields of material performance simulation, traditionally part of engineering practices, with architectural design practice.

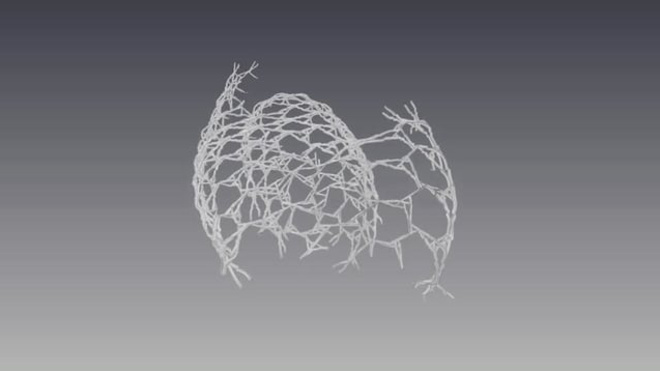

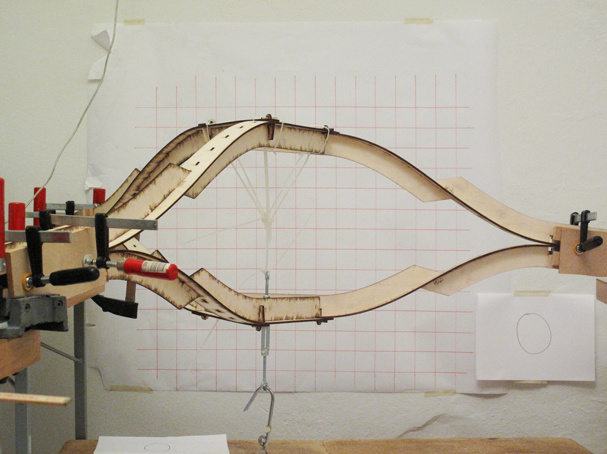

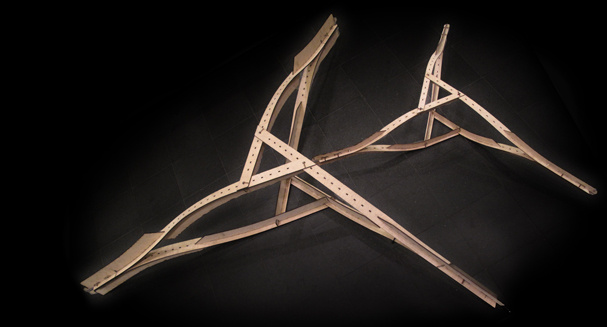

Through a two year collaboration within a series of workshops with faculty, PhD candidates and students a reciprocal frame system made of individually shaped and flexed plywood members was developed. Speculative probes and prototypes in digital and physical models were driving the investigation and helped to develop large spanning aggregates of short members. The prototypes showed yet the high degree of interrelation between the elements, material and production. This necessitates a generative modelling approach that is holistic in nature and can simultaneously deal with the level of design, production, tectonics and assembly. The development was therefore conducted in a modular digital environment that consisted of exchangeable custom-made tools.

The modelling process differentiated between parts that operate on parameters that are directly dependent on others and those that are highly interdependent and need to interact mutually. Where the first are mainly positioned on the level of detail and construction and were managed in the parametric modeller of the Rhino CAD that generated finally the production files for the lasercutting of the plywood we used the nucleus physics engine of Maya™. Here a time-based process was established were the concurrent parameters on the level of design, structure, material, production and assembly could be solved. The process allows an intuitive near to real-time design process of complex structures with manifold topologies.

A first Dermoid structure was built for an exhibition in spring 2011. The invitation to build a similar structure for the Copenhagen Design Week 2011 gave the possibility for a new site specific design of the structure and to extend the research question of the project. How to integrate simulation based knowledge on the structures behaviour into the design process? How can this feedback influence and improve the structure through the grading of material thickness, beam and element dimensions.

As the main goal of the design with the physics engine is to enable fast iterations of the design the constraints the time expensive calculation of structural performance is not integrated. However structural aspects have a relevant influence on the gridshell’s performance. Structural analyses afford the required information for a higher optimisation in terms of deformations and material utilisation. By means of FE-Modelling, the resulting sectional-forces and nodal displacements can be calculated and the influence of diverse geometric parameters can be analysed. This information could be fed back into the design environment were the beam arrangement and cross-section designations can be redefined.

The optimisation and redefinition of the Dermoid gridshell was possible thanks to an iterative exchange of information between the parametrically-defined design and the FEM-based structural models.

Support

Velux Guest Professorship, CITA / Mark Burry, SIAL.